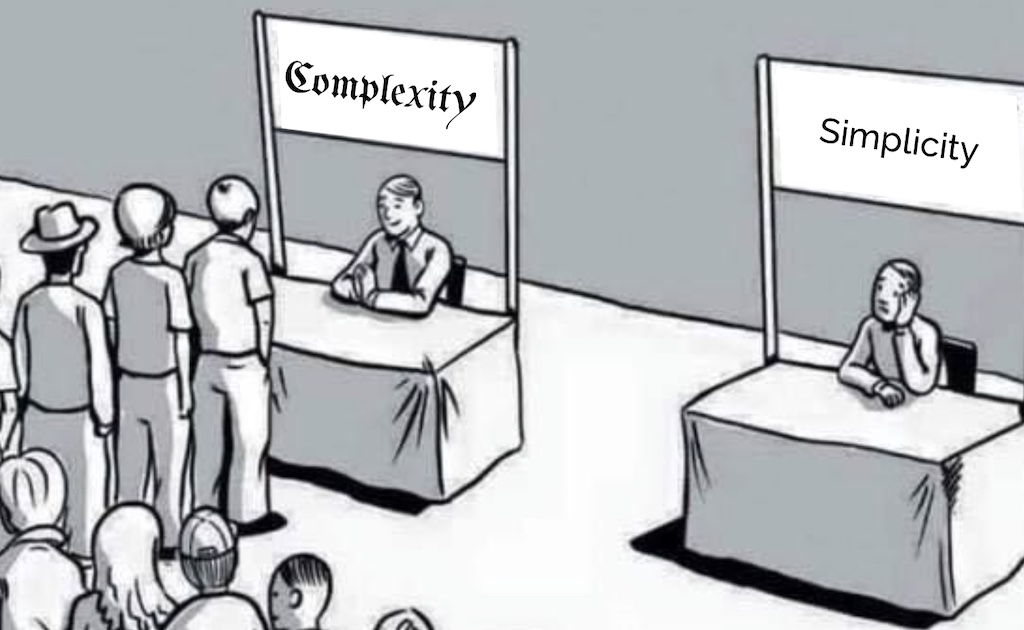

Throughout my career, I have adhered to a guiding principle: reduction of complexity in both instrument servicing and organisational processes. The simpler the system, the more stable it will function as it operates and/or scales into more complexity.

Strategic Management in Manufacturing Organisations as Complex Adaptive Systems

Technical Service organisations, particularly those belonging to manufacturers, today are grappling with significant operational complexities, driven by rapid technological advancements, global supply chain dynamics, and evolving consumer preferences. Traditional strategic management, often linear and hierarchical, struggle to keep pace with these challenges.

A more contemporary and robust framework views these organisations as Complex Adaptive Systems (CAS). This perspective not only aligns with the inherent complexities of modern manufacturing but also offers strategic resilience and adaptability.

Understanding Complex Adaptive Systems

Complex Adaptive Systems are characterised by diverse, interdependent agents that interact in dynamic and non-linear ways. These agents include human resources, machinery, technologies, supply chain partners, and market forces. The interactions among these agents give rise to emergent behaviors and patterns that cannot be predicted by analysing individual components alone.

The key attributes of organisations as CAS include:

- Non-linearity: Outcomes are not directly proportional to inputs. Small changes can lead to disproportionate effects, necessitating a nuanced approach to strategic planning.

- Adaptability: Agents within the system continuously adapt based on feedback from the environment, fostering resilience and innovation.

- Emergence: Complex behaviors and patterns emerge from simple rules and interactions, underscoring the importance of fostering conducive environments rather than dictating outcomes.

Strategic Management Through a CAS Lens

Adopting a CAS approach to strategic management in manufacturing entails several critical shifts:

- Embracing Uncertainty and Flexibility: Traditional strategic planning often hinges on forecasts and stable environments. However, modern organisations must embrace uncertainty as a continuous pressure. Fostering a Culture of Continuous Learning: In a CAS framework, the ability to learn and adapt is paramount. Manufacturing organisations must cultivate a culture where continuous learning and innovation are embedded in everyday operations. This involves investing in employee training, encouraging cross-functional collaboration, and leveraging data-driven insights to inform decision-making.

- Decentralised Decision-Making: Given the non-linear and emergent nature of CAS, centralised decision-making can be a bottleneck. Empowering teams at all levels to make decisions fosters faster response times and more localised solutions. This decentralisation requires robust communication channels and a shared vision to ensure alignment and coherence.

- Leveraging Technology and Data Analytics: Advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning are instrumental in navigating the complexities of modern manufacturing. These technologies enable real-time monitoring, predictive maintenance, and optimised supply chain management. Data analytics, in particular, plays a crucial role in identifying patterns, anticipating disruptions, and informing strategic choices.

- Building Resilient Supply Chains: Supply chain disruptions can have cascading effects in a CAS. Therefore, building resilient supply chains is critical. This involves diversifying suppliers, adopting just-in-time inventory practices, and implementing robust risk management strategies. Collaboration and transparency with supply chain partners further enhance resilience and adaptability.

Success within a complex service environment come through building an effective team that are able to operate flexibly with non-linear business challenges. Having a clear vision, strategy and plan that acknowledges the non-linear challenges and aims to address each input.

Example 1: Failure to Repair

If a new device fails, then it is the role of the service team to identify the cause of that failure and correct it. Assuming a device is being used as it was designed to be used, then the fix should simply be to return the instrument to its original condition – that is, in the same state that it left the production line. If it was built correctly and adjusted correctly, then making sure it is still built correctly and adjusted correctly should mean that it works correctly again. Simple.

If a service technician fails to identify and repair the root cause error, they may set the device onto a path of non-linear sub-optimal performance. As a result, the devices fail more and more often and the cause of that failure cannot be isolated to a single issue despite increasingly desperate attempts to do so.

Example 2: Process Complexity

So many of our businesses are run with processes that are in place to fix a problem downstream of the complex system. They see a problem and then add a new layer into the process in an attempt to correct the issue, only increasing complexity and creating problems further downstream. The situation repeats until the business becomes so burdened by procedures and processes that it functions inefficiently (high costs, low satisfaction, lots of ‘spot fires’ day-to-day).

Furthermore, new staff take a long time to onboard, and losing long serving staff has an outsized impact on the business operations. You will know these organisations when you hear the chilling tell-tale phrase, “Oh, that’s just how we do things here”.

Final Words

Managers in technical organisations must internalise these principles and continuously refine their approaches to thrive in the this complex operations world. By doing so, they can ensure that their organisations not only survive but also flourish within complex systems.

Good managers must seek to identify the upstream problems and correct them at the source to minimise the non-linear impact on the organisation downstream, whether that is in instrument operation, operational process, supply chain efficiency, and even customer satisfaction and overall business performance.